Table of Contents

Report

Rubbish robot

Author(s):

- Corina Tuluc

- Frederique Verberne

- Szymon Lasota

- Tomás de Almeida

Acknowledgement

Glossary

| Abbreviation | Description |

|---|---|

| EPS | European Project Semester |

| ISEP | Instituto Superior de Engenharia do Porto |

| USB | Universal Serial Bus |

| EU | European Union |

| B2B | Business to business |

| B2C | Business to customer |

| PESTEL | Political, Economic, Social, Technological, Environmental, Legal |

| SWOT | Strenghs Weaknesses Opportunities Threats |

| 2D | 2 Dimensions |

| 3D | 3 Dimensions |

| C | Corina Tuluc (team member) |

| F | Frederique Verberne (team member) |

| H | Hilary Haskings (team member) |

| J | Jannes Fürstenau (team member) |

| S | Szymon Lasota (team member) |

| T | Tomás de Almeida (team member) |

| PLA | Polylactic Acid |

| CAGR | Compound Annual Growth Rate |

| WIPO | World Intellectual Property Organization |

| IFR | International Federation of Robotics |

| LIDAR | Laser Imaging, Detection, and Ranging |

| FNSS | Fast Network Simulation Setup |

| CNC | Computer Numerical Control |

| Team | Team 2 |

| DC | Direct Current |

| FEFCO | European Corrugated Packaging Association in Brussels |

1. Introduction

1.1 Presentation

This is TEAM 2, a group of international students from different countries, cultures, with different fields of study who speak different languages completing a European Project Semester at Instituto Superior de Engenharia do Porto. Team2 has chosen to design and build a simulation of a robot that cleans the inside buildings. This semester they will research, sketch, model, and prototype a robot and improve it at every stage we have. The group consists of 4 people; Corina from Romania studying Telecommunications Engineering, Frederique from the Netherlands studying Civil Engineering, Szymon from Poland studying Business and Technology, and Tomás from Portugal studying Mechanical Engineering. Since some team members left Team2, due to the COVID-19 circumstances, Melissa Boularas is supporting Team2 with the extra contribution to the project. Melissa Boularas is studying Environmental Engineering in France and Team2 is of course very pleased with her contribution to the project. In Table 1 is an overview of the team members of Team2.

1.2 Motivation

Rubbish is a serious problem. The world today is looking at smarter ways of overcoming the waste problem altogether. We believe an autonomous robot would help solve this problem. It is proven that a clean space around you helps to reduce anxiety, tension and gives you mental clarity and is healthier for you. We want to help people to always have the opportunity for a clean environment in an effective way. We also considered that this is a very challenging project which will give us the opportunity to use all our fields of study. It is also a great opportunity to work with different students from different countries and to get to know each other better. We also want to improve our foreign language and communication skills and to work out of our comfort zone.

1.3 Problem

Rubbish and waste products are one of the biggest problems that the earth is facing. Nowadays, management of the rubbish from its collection point to the point of recycling has become one of the biggest challenges for municipal corporations all around the globe. Waste removal is an area where more humans are required. The present methods of waste collection have been proven ineffective. Team2 wants to help solve this problem by creating an autonomous robot that will clean the inside the buildings without human help. Think about university halls, malls, government halls, etc.

Problems that might appear while developing this project are:

- Time - The design and simulation of the robot has to be done by June

- Budget - 100 € might not be enough

- Covid-19 - Possibility to break up the team and physically working together is not possible

- Safety- The robot has to be safe and to not disturb other humans while in operation

- Programming and hardware - Collectively we don't have a wide enough knowledge in this field

1.4 Objectives

Our main objective is to create a sustainable waste robot that can clean the insides of buildings in an efficient and safe way with limited human interaction. This product requires design and imagination to build an innovative product that helps to solve one of the biggest challenges in today's world.

1.5 Requirements

The requirements given to us by the course leaders are the following:

- Comply with the following EU Directives:

- Machine Directive (2006/42/CE 2006-05-17);

- Electromagnetic Compatibility Directive (2004/108/EC 2004 12 15);

- Low Voltage Directive (2014/35/EU 2016-04-20);

- Radio Equipment Directive (2014/53/EU 2014-04-16);

- Restriction of Hazardous Substances (ROHS) in Electrical and Electronic Equipment Directive (2002/95/EC 2003-01-27);

- Mandatory adoption and use of the International System of Units (The NIST International Guide for the use of the International System of Units)

- Design, build and test the robot

- Use open source software and technologies

- Use sustainable solutions

- Use low cost hardware solutions

- Easy maintenance

- Recyclable components

- Continuous and efficient cleaning

- Not exceed the budget of 100 euros

1.6 Functional Tests

The team thought about some tests that could be important to realise and guarantee a working product such as:

- Motor rotational speed test

- Motor torque test

- Storage box emptying test

- Fan test

- Obstacle behaviour test

- Indoor coordination test

1.7 Project Planning

Project Planning is developed based on the Scrum and Agile methodologies, see figure 1. This methodology involves creating a product backlog which includes all the things that must be done to complete the whole project effectively. After that, the “sprint” planning based on the tasks from the backlog. The sprint backlog is like a subset of the product backlog. The sprint backlog comes from the product backlog, but it contains only that item(s), that can be completed during each sprint. The sprint length for us is one week. After that, we have to decide which team member would do each task and the time allocated for it.

1.8 Report Structure

The following Table 2 shows the 8 different chapters and the content of them that the reader can have a look at.

| Chapter | Task | Description |

|---|---|---|

| 1 | Introduction | Presentation of the team members, motivation, project purpose, objectives, requirements and project planning |

| 2 | State of the Art | Research of different existing products or prototypes on the market |

| 3 | Project Management | Documentation of the progress including all the tasks based on the agile management and SCRUM |

| 4 | Marketing Plan | Identification of the target group and building of our strategy for introducing the product in the market |

| 5 | Eco-efficiency Measures for Sustainability | Analysis of the economical, environmental ,social and life cycle of the product |

| 6 | Ethical and Deontological Concerns | Analysis of ethical limitation and their solutions |

| 7 | Project Development | Analysis of the steps to follow throughout the whole project |

| 8 | Conclusions | Results and future improvements that can be made |

2. State of the Art

2.1 Introduction

The development of a rubbish-collecting robot is going to be discussed. This is done by collecting data about already existing projects that are similar to the product we will develop and comparing those solutions with each other.

The state of the art chapter is dedicated to getting a broad overview of the current market situation, this not only helps the team with creating ideas to implement but also aids an understanding of what is important while building a waste-collection robot and seeing existing products as part of our own solution.

The group went about this by researching a variety of different solutions. All products and prototypes shown in this chapter have some aspects that we think will be worth considering.

We considered solutions for indoor and outdoor applications.

The research here is mainly focused on products that provide solutions to the following problems:

- Mechanism for transporting rubbish into internal storage

- Mechanism for moving the robot

- Mechanism for coordinating the robot

To organize the multitude of different products and prototypes, we divided them into two main categories that are “non-autonomous systems” and “autonomous systems”. The two main categories are also divided into sub-groups as can be seen below.

2.2 Non-Autonomous Systems

2.2.1 Manual Rubbish Collector

Rubbish collectors (sometimes known as Refuse Collectors), represent the low-tech solution to dealing with society’s problem of waste pollution. They are hired to keep the public environment clean. Refuse Collectors can either be employed by state-owned or private companies. Although most people associate Refuse Collectors with the people driving bin lorries and emptying rubbish bins, the range of tasks of refuse collectors varies.

In this chapter, we will not focus on the Rubbish Collectors that are removing rubbish from civil and commercial spaces with vehicles, but instead concentrate on the ones whose task is clean using a broom 2 and a catcher 3 from public places such as squares, streets or parks.

Rubbish collectors can rely on a broad variety of tools, depending on their specific tasks. You often see them cleaning with tools such as a dustpan and brush. But also tools like a litter picker are commonly used to pick up specific rubbish like cigarette butts.

The job of a Rubbish Collector, in general, is considered to be an unpleasant job, although the median hourly wage of Refuse collectors is, for example in the US is 15.50 € [2], compared to a minimum wage of 6.75 €.

The downside for many people of course is the work environment which, due to its nature isn't very hygienic. One of the most important aspects of the job is the physical burden. The job itself is physically demanding meaning most people are not able to continue with this job for a long period of time. Considering this fact, it is even more surprising that companies widely still employ people to do this job rather than find and switch to high-tech solutions.

The Figure 2 and Figure 3 show some solution of rubbish collector.

2.2.2 Vacuum Cleaners

2.2.2.1 Home Vacuum Cleaners

2.2.1.1.1 Cable-connected Vacuum Cleaners (AEG VX8-3-FFP)

The AEG VX8-3-FFP (see Figure 4) is a common corded vacuum cleaner. It consists of a power unit, a suction vacuum, a flexible hose, and a floor nozzle. A cable of 12 meters is attached to allow mobility inside the house. With the use of cable retraction, the cable will not get in the way of the user when the product is not in use. The product has two wheels attached at the back which are fixed to an axis and made of a soft rubber material so as to not scratch any surface material inside the house.

Users of this AEG report the device is very powerful compared to other home-use vacuum cleaners but one of the most interesting facts about this cleaner is the degree of noise production. The AEG only produces 64 dB of sound when in operation which is extremely low in comparison with other home vacuum cleaners. This comes close to the noise levels produced when talking to someone on the telephone. AEG promoted this feature with the term “silent air technology”. The plastic body of the device contains a dirtbag (see Figure 5) in which all objects that are sucked in will be stored. There is a display that shows the status of the storage load and tells the user when the bag has to be replaced.

Some characteristics about the AEG VX8-3-FFP can be seen on Table 1.

| Category | Value |

|---|---|

| weight | 6 kg |

| dimensions | 402 x 308 x 266 mm |

| storage | 3.5 l |

| max. power | 650 W |

| voltage | 220-240 V; 50/60 Hz |

| price | ca. 150 € |

2.2.1.1.2 Battery-powered Vacuum Cleaners (Dyson V8 absolute)

Dyson is known to be one of the best-known vacuum cleaner producers. Their products are considered to be modern, efficient and elegant.

The Dyson V8 absolute (see Figure 6) has two different suction modes for different degrees of pollution. The battery-powered system is easy to handle for everyone because of its reduced weight, after using the vacuum cleaner it can be attached to a bracket, that is typically placed to the wall. This bracket is used as a charging station at the same time.

The cleaning part of the system is equipped with an electric brush with a direct drive and a soft roller to make sure all of the dirt is collected. The device has an easy unloading mechanism, that works with a button that opens a door below and lets the dirt fall down. There is no bag attached, the dirt is stored directly in a small cylindrical container.

The system works with 15 cyclones that create a strong centrifugal force to capture even microscopic dirt. The vacuum cleaner has a filtration system that captures allergens and expels cleaner air than the air the human breathes. Dyson therefore advertises the product with being asthma and allergen friendly. They also have a certificate for this.

Some characteristics of the Dyson V8 can be seen on Table 4.

| Category | Value |

|---|---|

| weight | 2.55 kg |

| dimensions | 250 x 1244 x 224 mm |

| storage | 0.54 l |

| max. power | 425 W |

| voltage | 200-253 V; 50/60 Hz |

| run time | 40 min |

| charging time | 330 min |

| price | ca. 320 € |

2.2.2.2 Industrial Vacuum Cleaners (Nilfisk Multi II 30T INOX VSC EU)

The Nilfisk Multi II 30 T INOX VSC EU is a typical industrial cleaner like you can see on Figure 7. It is mostly known for use in factories or in general environments with a lot of pollution such as house renovations. The Vacuum cleaner is not only able to clean in dry but also in a wet environment which is important for industrial use. The Nilfisk can even dry out whole pools, with several loads. It can be used in four different modes, increasing the suction power. With increasing power levels, also the noise increases. The highest mode makes sounds of 76 dB.

The Nilfisk has a big cylindrical steel container to store the dirt in with a high volume of up to 30 L as is showed on Table 5. The size of the product results in a heavier weight, which makes the vacuum cleaner relative immobile. To counteract this, the Nilfisk has two wheels in the same axis, that allow a tilted pulling, and also two smaller wheels that are 360 degrees rotatable.

The device has a regulation mechanism to control the suction power and is equipped with a filtration system that will send a notification to a display if the filter is blocked. The filter is washable and therefore can be reused after cleaning.

| Category | Value |

|---|---|

| weight | 10.5 kg |

| dimensions | 426 x 374 x 684 mm |

| storage | 30 L |

| max. power | 1400 W |

| voltage | 220-240 V; 50/60 Hz |

| price | ca. 300 € |

2.2.3 Basic Sweeping Machines

2.2.3.1 Haaga 677 profi

The “Haaga 677 profi” (see Figure 8 is a sweeping machine that can either be run in manual mode, in which the device has to be pushed, or in electrical powered mode where the device still has to be pushed but it's much easier to push it and the device motion only has to be controlled.

The “haaga 677 profi” can collect fine and rough dirt and other elements of pollution. The maximum size of the rubbish collected is limited by the height adjustment feature. Also, the condition of the collected objects can differ. That means the sweeping machine is able to collect dry objects as well as wet objects such as wet leaves. This device can be used in various environments. The manufacturer advertises the product for parking lots, farms or factories.

It works with two big plate brushes that sit at the front of the machine and spin in the opposite direction pushing any source of the object to the center of the cleaned track. There are little wheels on the side, protecting the machine as well as the wall or object it would otherwise hit. Attached to this there is a small hold down feature that is used to push down the brushes collecting dirt also in the corners. Behind the two plate brushes that are positioned vertically is one more horizontal brush that collects smaller objects and particles so they land in the big storage receptacle at the back of the machine (see Figure 9). With this mechanism, the manufacturer promises you will be able to collect dirt from an area as large as 3600 m² in one hour.

Some characteristics of the Haaga 677 profi can be seen on Table 6.

| Category | Value |

|---|---|

| weight | 20.2 kg |

| sweeping width | 770 mm |

| storage | 50 l |

| voltage | 12 V |

| run time | 90 min |

| charging time | 420 min |

| price | 640 € |

2.2.3.2 Agria 7100 cleanstar basic

The “Agria 7100 clean basic” is an engine-powered sweeping machine (see Figure 10). It is built for outside use. While the machine can be used to clean the ground of several different types of waste, this device is mainly used as a snowblower. The engine is a four stroke-type Honda GCV-135, that generates 3.5 kW of power. The engine works with petrol. The “agria” can drive at a speed of 2.4 km/h.

This sweeping machine has only one big horizontal brush. The brush bristles are relatively stiff so large quantities of dirt, rubbish or snow can be removed. The brush can be turned so the direction can be adjusted. The user holds on to two grips that have brakes for motor and brushes attached.

Directly under the engine, there are two pneumatic wheels that allow movement on uneven terrain.

The technical data about the Agria 7100 can be seen on Table 7.

| Category | Value |

|---|---|

| weight | 68 kg |

| sweeping width | 700 mm |

| storage | different bags available |

| max. power | 3500 W |

| speed | 2.4 km/h |

| price | ca. 1800 € |

2.2.4 Cleaning Vehicle

2.2.4.1 Eureka Rider 1201

The “Eureka Rider 1201” is a ride-on cleaning vehicle as you can see in Figure 11 and Figure 12. It is not made only for indoor applications, but can be used in some outdoor environments as well. The sweeper has two big plate brushes at the front. They are extendable and increase the width of cleaning from 70 cm to 120 cm.

The “Eureka” is available in two editions; there is a petrol-powered engine that is fuel-efficient and there is a battery version that has no emissions and therefore suitable for indoor use. It's also much quieter than the combustion engine version.

Right behind the two vertical plate brushes, there is another horizontal rotating brush, that automatically adjusts to the surface beneath. The system can clean up to 10000 m² in an hour.

On the back of the vehicle, there is storage attached that can be taken out and emptied in a few seconds. The device also has an industrial vacuum cleaner attached, that can be used for more narrow positions

“Eureka Rider 1201” has an efficient bag-filter system made of polyester. It can be automatically emptied by a filter-shaker. The filter can also be taken out and be washed, this ensures the filter’s long life.

The technical data about the Eureka Rider 1201 is available on Table 8.

| Category | Value |

|---|---|

| weight | 426 kg |

| dimensions | 1210 x 1545 x 1250 mm |

| sweeping width | 1200 mm |

| storage | 85 l |

| max. power | 1200 W |

| speed | 7.7 km/h |

| price | unknown |

2.2.4.2 Kärcher KM 170/600 RD

“Kärcher KM 170/600 RD”, showed on Figure 13 is a ride-on vehicle that can clean and remove dirt and waste from any surface and also any source of rubbish or other pollution. It is mainly used for construction site clean-up. The vehicle is a high-end product with a variety of useful features.

Powered by a strong diesel-engine this four-wheel vehicle has no problems getting along in rough conditions like metal-working industries or in building-material industries. A variety of different plate brushes and roller brushes can be attached to this vehicle. The car has friction control, forward reverse, and a filter area as big as 10 m². The container can automatically be emptied even in the higher position (up to 1.52 m) by a hydraulic system. Power steering supports the driver and lets them coordinate the vehicle easily and accurately.

The technical data about the Kärcher KM 170/600 RD is available on Table 9.

| Category | Value |

|---|---|

| weight | 1530 kg |

| dimensions | 2742 x 1904 x 2213 mm |

| sweeping width | 2000 mm |

| storage | 600 l |

| max. power | 35000 W |

| speed | 14 km/h |

| price | ca. 70000 € |

2.2.5 Street Cleaning Vehicle

2.2.5.1 Bucher municipal Citycat 1300

The “Bucher municipal CityCat 1300” (Figure 14) is a street cleaning vehicle but it can also be used for cleaning other smooth surfaces like tarmac. The driver of this vehicle sits in a closed glass cabin, which protects them from dust, rubbish, noise and odor but, at the same time, allows him a good overview so he can steer the vehicle accurately.

This vehicle, which is powered by a diesel engine can have two or four plate brushes at the front that collect rubbish and dirt from a large width of more than 2 m. The brushes are sprayed with water from the water tank with a capacity of 225 L. This allows a better binding of the dirt and gives it a much better cleaning result. The vehicle can store 800 Kg of rubbish and dirt in a large container, which can tilt to facilitate unloading of the waste at the back of the vehicle. The waste is deposited there by a suction system that sits directly behind the large plate brushes and transports the rubbish into the container as you can see in Figure 15. The filter is placed on top of the storage system.

The technical data about the Bucher municipal Citycat 1300 is available on Table 10. More details are shown in Figure 16.

| Category | Value |

|---|---|

| weight | 2800 kg |

| dimensions | 3300 x 1110 x 1930 mm |

| sweeping width | 2200 mm |

| storage | 1300 l |

| max. power | 31200 W |

| speed | 25 km/h |

| price | unknown |

2.3 Autonomous Systems

2.3.1 Home Cleaning Robots

2.3.1.1 Roomba

The Roomba robots, showed on Figure 17 is one of the most well known and also expensive brands of home cleaning robots [18]. The robot works completely autonomously and cleans in three steps: agitation, brushing, and suction. It uses one vertical brush (some new models use two) two horizontal fans and a vacuum system. Although their sensors are very good the robot can miss spots from time to time.

The technical data about Roomba is available on Table 11.

| Category | Value |

|---|---|

| weight | 4 kg |

| dimensions | 353 x 353 x 91 mm |

| capacity | 0.6 l |

| max. power | 33 W |

| battery | 3300 mAh |

| price | ca. 800 € |

2.3.1.2 Xiaomi MiRobot

This is a mid-range price robot that is very similar to the Roomba, as you can see on Figure 18. This has the same method of cleaning as Roomba (three steps) but the quality of the sensors that detect any obstacles is not as good but despite this it's capable of cleaning as well as a Roomba robot [20].

The technical data about Xiaomi miRobot is available on Table 12.

| Category | Value |

|---|---|

| weight | 3.5 kg |

| dimensions | 353 x 353 x 96.5 mm |

| capacity | 0.48 l |

| max. power | 50 W |

| Battery | 5200 mAh |

| price | ca. 330 € |

2.3.1.3 eufy Anker RoboVac 30

This is the lower-priced vacuum robot, showed on Figure 19. The system to catch the rubbish and dust is the same as the others but this product uses two vertical brushes. Also, the battery is small which reduces the working time by about 20 minutes when comparing it to the other robots but it is more power-efficient needing just 25 Watts to work. The downside is that the materials used are of poor quality and this is noticeable on the electronic system when the robot gets “stuck” around objects [22].

The technical data about the eufy Anker RoboVac 30 is available on Table 13.

| Category | Value |

|---|---|

| weight | 2.7 kg |

| dimensions | 325 x 325 x 74 mm |

| capacity | 0.6 l |

| max. power | 25 W |

| battery | 2600 mAh |

| price | ca. 240 € |

2.3.2 Street Cleaning Robots

2.3.2.1 ENWAY Autonomous Sweeping

This machine was created and developed in Germany and was designed to clean city streets and public spaces [24]. Along with the software, the vehicles use a combination of LIDAR, cameras, radar, FNSS, and wheel odometry to navigate. Robots can be programmed to follow human workers with the aim of making refuse collection safer and more efficient. The path to clean squares uses an “S” circuit to cover all areas. It uses two vertical brushes and a vacuum system to catch the waste[25] as is showed in Figure 20.

The technical data about the ENWAY Autonomous Sweeping is available on Table 14.

| Category | Value |

|---|---|

| weight | 850 kg |

| dimensions | 2170 x 1350 x 1770 mm |

| capacity | 150 l |

| max. power | unknown |

| Battery Autonomy | 6 hours |

| Max Speed | 8 km/h |

| price | unknown |

2.3.2.2 DustClean

DustClean is an autonomous mobile robot equipped with brushes and containers for sweeping and collecting rubbish from the ground and designed for the cleaning of urban pedestrian areas such as parks, roads and squares, as you can see on Figure 21. DustClean can operate autonomously and safely using preloaded information for its environment such as a map of the area and information coming from the on-board sensors. The robot is able to follow a working path planned autonomously or defined by a user to avoid hitting obstacles during navigation [27].

The technical data about the DustClean is available on Table 15.

| Category | Value |

|---|---|

| weight | 150 kg |

| dimensions | 1651 x 1123 x 1060 mm |

| capacity | 37 l |

| max. power | 400 W |

| Battery | 100 Ah |

| Max Speed | 3 km/h |

| price | unknown |

2.3.3 Home made projects

2.3.3.1 CleanSweep

This is a homemade project built by Saiyam Agrawal. This robot was designed to clean the floor with water and soap using two mops on the front of the device. This project is not autonomous because it needs a user with a smartphone to control the movements of the robot.

The prototype is showed on Figure 22.

2.3.3.2 Automatic Vacuum Cleaner Robot Project

This robot is an autonomous vacuum cleaner, as you can see on Figure 23. It uses zero brushes to collect the rubbish, using just the vacuum system to suck the dust and waste. The robotic system follows a zigzag path to cover the entire room and uses ultrasonic sensors and operates accordingly in order to cover the entire room. There should be no obstacles in the entire room for this system to work properly [30].

2.4 Conclusion

In the introduction of this chapter, the team defined the main issues that the research is focused on. While also researching on other similar projects, the biggest part was still dedicated to finding solutions to the following problems:

- mechanism of transporting waste into internal storage

- mechanism of moving the robot

- mechanism of coordinating the robot

Regarding the aspect of transporting waste into the internal storage the team recognized, that vertical brushes are used in every kind of waste removal device, regardless of the size of the device, kind of dirt or rubbish to clean or work environment. With the rubbish getting more robust, the bristles have to be more durable as well, but as the team is designing an inside working robot with mostly soft and small sources of pollution, a soft bristles material might be fitting. Often to transport the dirt into the storage, similar products make use of horizontal brushes as well. Some devices even have two horizontal brushes installed. As a team we consider this a good idea and might also implement it into our project. A lot of products are also equipped with a suction system. A suction system gives the big advantage that it can carry dirt and rubbish against the force of gravitation and therefore makes a bigger volume of storage inside the robot possible because the point of entrance for the dirt can be placed higher. Nonetheless, the team has to consider energy consumption, the suction system is probably consuming a lot of energy and might not be implemented that easy.

Looking at the mechanism of moving the robot, a chain drive was considered a good option by the team before the research. However, the research showed that most commercial cleaning devices have a wheel system. Big systems like the “Kärcher” have pneumatic wheels, but as our robot is supposed to be as compact as possible, a full-material rubber seems like an appropriate option. The team though has not come to a conclusion regarding the number of wheels that shall be used. Most similar-sized options have two wheels on the back, but not all have one or two wheels at the front. More research and discussion is needed regarding this feature.

With the mechanism of coordinating the robot in the room, the team first thought about the lawn mowing robot’s technology seemed like a good option. As the cable to navigate has to be put into the solid ground of shopping centers and similar buildings, the team decided to distance themselves from this idea, as the expenditure would be way too high, and by this the number of potential customers would be a lot smaller. A detection mechanism with ultrasonic sensors seems like a much simple, and therefore better idea.

Based on this study of the state of the art, the team got a much better overview about already existing products that might help them with developing a prototype, more technical research has to be done in some aspects, to find the best option in each aspect, and by this developing the best possible rubbish-collecting robot at the end of the project.

3. Project Management

Project Management is the application of knowledge, skills, tools, and techniques to project activities to meet the project requirements [32]. Correct project management will provide the project to run smoothly.

To do so, in this chapter, the following topics will be discussed:

- Scope

- Time

- Cost

- Quality

- People

- Communications

- Risk

- Procurement

- Stakeholders management

- Sprint outcome

- Sprint evaluations

3.1 Scope

Scope in connection with project management can mean two things: on one hand, there can be a Product Scope that defines functions and features of the product. On the other hand, there is the Project Scope. In opposition, this scope deals with work and tasks that must be done to realize the functions and features that were set by the team before as part of the Product Scope.

Developing a Scope in projects is important because it helps the team to keep a global overview of tasks already finished and tasks to be done. Thereby the team will not put time and work into tasks that are not important to the project at this moment in time. The Scope also helps with distributing tasks and increasing the team’s overall efficiency.

To visualize Project Scope it is common to set up a Work Breakdown Structure (WBS). In Figure 24 the WBS of the EPS project is displayed. The team divided the project into six different main groups, each containing several smaller tasks. After creating the Work Breakdown Structure, it is also important to validate the scope as the project proceeds and to control the whole scope as the project is about to be finished.

3.2 Time

Time is very important when it comes down to managing a project. Like all projects, this project has an end date. Not only is the end date important for the project, but also the deadlines in between are an important key in the process. To manage the project correctly, a time table is useful.

Two processes are important to keep in mind when using a timetable. First is ‘what’. What do we put down on the timetable? Which components are important to make a milestone and what is the critical path of your timetable? To decide these components, the use of the deadlines are the main guidelines to follow, these are the milestones. This is because the deadlines are well structured to the process. When the deadlines are used as milestones, the timetable is built to work towards these milestones. Besides reaching the milestones, there’s also a critical path. This means that certain activities have a major influence on the end date. When knowing these activities, a buffer can be implemented so the end date will still be maintained.

The second important process is ‘who’. Who is responsible for the control of the timetable? And who is cooperating with the project? The answer to this second question is important for the time that an activity will take. By knowing this, the needed time can be determined. The answer to the question ‘Who is responsible?’ needs to be defined by the team. One team member carries the responsibility to follow and control the timetable. He or she will be responsible for following the timetable and adjusting the timetable when activities are postponed.

3.3 Cost

By managing and controlling the cost of a project, it allows a business to predict incoming expenses in order to reduce the chances of it going over the budget.

3.4 Quality

To ensure the success of the project, it is most important for the team members to check every aspect of the project for the highest quality option. Quality is defined as “the degree to which a set of inherent features of an object meets requirements” [33].

In our specific case, and considering that we aren’t professionals in project management, the quality of teamwork might be most crucial to the degree of success in this project, but there are more aspects that have to be checked, for example, the quality of components or quality of assembly.

Quality of Teamwork: To make sure our work has the highest possible quality, we introduced some procedures. It is important that research, calculations, tasks and English are always double-checked by another person. This prevents careless mistakes and thereby insures quality in these tasks.

When distributing tasks to the team members, we make sure that the kind of tasks not only fit the person’s skills but also the person’s interest. By doing so, the motivation of the team members stays high during the tasks, which leads to a higher quality of work in the end.

As we are supervised in this project by a team of teachers, we are also willing to take any advice or help that we get and try to realize the proposals as detailed as possible.

The most important part of the quality of the project’s teamwork is the mindset of every single team member. Everyone has to make sure, they are contributing the best they can and are able to see when they are not right on a specific subject.

Quality of Components: For the highest possible quality of components,the team makes sure they have chosen providers that can deliver components in a quality that suits the use of the individual component. To be able to find suitable quality components, it is vital to define the task of the components beforehand.

Doing this, there can be components that are broken or are not delivered in perfect condition. For those cases, the team will check components as soon as possible after delivery and contact the provider about a new component.

Quality of Assembly: As not all of the team members have set up a robot before, it will be important to research about an assembly of similar machines. Because the components are expensive and the budget of the project is very limited, it is of highest priority to make sure the plan of assembly can be realized and will work in the way planned, so the risk of destroying certain components during assembly will be minimal.

To insure quality, project managers often use quality matrix-like seen below in Table 16.

| Field | Description | Value |

|---|---|---|

| Internal & Work Ethics | ||

| Finances | Budget | 100 € |

| Logistics | Local Providers | within 100 km of Porto |

| Electronics | ||

| Power | Low Power Consumption | |

| Obstacle detection | ||

| Cleaning | ||

| Result | Degree of Cleanliness | no visual dirt and waste |

3.5 People

The Responsibility Assignment Matrix can be used to distribute the different tasks to the six-team members. It helps with getting an overview and distributing workload equally so that none of the team members has to work too much while another person has free capabilities. A Responsibility Assignment Matrix (RAM), also known as RACI matrix or Linear Responsibility Chart (LRC), describes the participation by various roles in completing tasks or deliverables for a project or business process [34].

The different roles are abbreviated as seen below:

R: responsible (person , who works on the specific task)

A: accountable (in some way a coordinator of the responsible, takes responsibility for the final outcome of the task)

C: consulted (the person whose opinion is relevant on a subject, usually an expert)

I: informed (person who will be kept up-to-date, only one-way communication, no direct form of output)

Table 17 show us the responsibilities divided by the team members.

| Task | Szymon | Corina | Frederique | Tomas | Hilary | Jannes | Supervisors |

|---|---|---|---|---|---|---|---|

| Task identification, brainstorming | R | A | R | R | R | R | C/I |

| Project Backlog | R | R | A | R | R | R | C/I |

| Gantt chart | I | I | A | I | I | I | C/I |

| Global Sprint plan | A | I | I | I | I | R | C/I |

| Initial Sprint plan | R | R | R | R | R | A | C/I |

| Technical research | R | A | R | A | R | R | C/I |

| Market research | A | I | I | I | R | I | C/I |

| Name and logo | R | I | I | I | I | I | C/I |

| Leaflet and flyer | R | I | I | I | I | I | C/I |

| Black box diagram | R | I | I | I | I | R | C/I |

| Structural drafts | I | I | I | A | I | R | C/I |

3.6 Communications

Communication is key to a project in which many people are working together. If the team is not communicating properly, a project will barely be a success. It is especially important in multicultural teams like in EPS because the team members might have different approaches dealing with problems or certain situations.

But communication is not only important within the project team, but it is also crucial between other stakeholders. For example, the customer should be kept up-to-date during the whole process of developing the project, because only then they can suggest changes or tell the team about doubts that they have. Otherwise, the doubts would be only expressed at the end, which would lead to a waste of time, work and money at the end.

Because of that, it is considered a good idea to set up a Communication Matrix, Table 18:

| Subject | Goal, Purpose | Involved groups | Time | Duration (typically) |

|---|---|---|---|---|

| Deliverables | ongoing progress of the project | team member responsible for the deliverable | deadline of the deliverable | - |

| Daily Video-Chat meetings | see workloads, difficulties, set up and change plans | team | every morning | 15 min |

| Agenda | introducing supervisors to the topics to be discussed controlling the direction of the meeting | team, supervisors | available for the supervisors no later than Wednesday afternoon | 5 min |

| Supervisor meeting | getting feedback about the progress and recent tasks | team, supervisors | every Thursday morning | 35 min |

| Technical supervisor meeting | discuss specific technical aspects, get an opinion on proposals | team, supervisors | no fixed dates | 30 min |

3.7 Risk

To look at the risk, it is important to look at what kind of risks there are and how we can control and manage these risks. In Figure 27 there is an overview of the risks.

3.8 Procurement

Procurement is the action of acquiring and buying equipment and supplies for our products. This is a very important part of building our product and any product in any business because without the proper equipment and materials there will not be any stable product.

Our team had a budget of 100€ for all the supplies to be used to build our product. This is why our team had planned the budget carefully and did specific actions:

- Compare the quality-price ratio from the available suppliers

- Take the maximum advantage of the material we have at our disposal

- Look for suppliers located in Porto or Portugal to decrease the shipping cost

The elective choice which local providers to be contacted in order to gain the components is crucial to building our product. There is a producing barrier regarding the plastic prototype printed components because we could only print it on ISEP and due to their dimensions we do not know if printing will be possible.

3.9 Stakeholders Management

Stakeholders are very important for a project. They influence the progress of the product and are a key role in the end result.

For the MOPBOT, a few stakeholders appear. To manage these stakeholders correctly, knowing how much interest and power they have on the product is important. Below, in Figure 28, the stakeholders for the MOPBOT product are put down. Knowing their role in the progress is important.

In the figure below Figure 29, the interest and power of each stakeholder are mapped.

3.10 Sprint Outcomes

The Sprint Outcome is a review of the work and tasks that were accomplished by the team during the sprint. The Outcome helps with improving the skill of expecting needed time more accurately and not get lost in the multitude of tasks. The following tables, Table 3 to Table 32 represent our weekly sprints.

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID001 | Black Box Diagram | ++ | S,J | 2 | 2 | Done | |

| ID002 | Brainstorming: Name and Logo | + | H | 1 | 1 | Not done | more brainstorming needed |

| ID003 | Proportions modell (CAD) | ++ | T | 5 | 6 | Done | |

| ID004 | Research on path system | + | F,J | 4 | 3 | Done | |

| ID005 | Backlog | +++ | team | 3 | 3 | Done | |

| ID006 | Global- and Initial Sprint Plan | +++ | J,T | 2 | 1 | Done | |

| ID007 | Gantt chart | +++ | F | 3 | 3 | Done | |

| ID008 | Function definition | +++ | team | 6 | 8 | Done | |

| ID009 | First sketches | ++ | T | 2 | 2 | Done | |

| ID010 | Personas development | ++ | team | 3 | 3 | Done | |

| ID011 | Comunication presentation | +++ | C,J | 3 | 3 | Done | |

| ID012 | Portuguese presentation | +++ | C | 3 | 3 | Done | |

| ID013 | Searching for the detection of the trash | ++ | C | 3 | 3 | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID011 | Improve Black Box Diagram | +++ | S,J | 1 | 1 | Done | |

| ID012 | First version: Project Management Chapter | ++ | F,J | 20 | 16 | Not done | A lot of improvement needed |

| ID013 | First version: Marketing Chapter | ++ | S,H | 20 | 20 | Not done | A lot of improvement needed |

| ID014 | First version: Sustainability Chapter | ++ | C,T | 20 | 20 | Done | A lot of improvement needed |

| ID015 | Logo sketches | ++ | H | 1 | 0 | Not done | |

| ID016 | Technical decisions | +++ | team | 6 | 4 | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID017 | First version: Ethics Chapter | ++ | H | 10 | 0 | Not done | Communication error |

| ID018 | Leaflet and Flyer | +++ | S | 5 | 8 | Done | |

| ID019 | Logo | +++ | S | 2 | 2 | Done | |

| ID020 | Improving Project Management Chapter | ++ | F,J | 10 | 0 | Not done | Postponed to next week |

| ID021 | Closing down on state of the art | +++ | J,T | 40 | 40 | Done | Some references not working |

| ID022 | Closing down on introduction | +++ | C | 6 | 6 | Done | |

| ID023 | Prepare Meeting with teacher Manuel | ++ | T | 1 | 1 | Done | |

| ID024 | Sustainability Chapter | ++ | C | 10 | 15 | Done | |

| ID025 | Component research | ++ | C | 5 | 3 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID026 | Slogan | + | S | 1 | 1 | Done | |

| ID027 | Calculations regarding surface, speed, size | +++ | J | 2 | 2 | Done | |

| ID028 | Improve Project Management chapter | ++ | F,J | 15 | 12 | Not done | |

| ID029 | Prepare Ethics presentation | + | T | 20 | 18 | Done | |

| ID030 | Detailed schematics | +++ | C | 15 | 1 | Not done | |

| ID031 | Structural Drawings | +++ | T, J | 10 | 10 | Done | |

| ID032 | 3D model | +++ | T, J | 15 | 15 | Done | |

| ID033 | List of material and components mechanical part | +++ | T | 20 | 20 | Done | |

| ID034 | List of material and components electrical part | +++ | C | 20 | 20 | Done | |

| ID035 | Ethics chapter | ++ | H | 15 | - | Not done | |

| ID036 | Market analysis | +++ | S | 20 | - | Not done | |

| ID037 | Planning changing due to situation | +++ | F | 20 | - | Not done | |

| ID038 | Research on the indoor localisation system | +++ | C | 20 | 15 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID039 | Finish chapter 6 | +++ | H | 10 | - | Not done | |

| ID040 | Chapter 7 conclusion | ++ | H | 5 | - | Not done | |

| ID041 | Update flyer | +++ | S | 2 | 3 | Done | |

| ID042 | Market Analysis | +++ | S | 10 | 10 | Done | |

| ID043 | Schematics | +++ | C | 15 | 15 | Done | |

| ID044 | Research on motors | +++ | T | 15 | 15 | Done | |

| ID045 | Update component list | +++ | T,C | 5 | 7 | Done | |

| ID046 | Ethics presentation | + | T, J | 10 | 10 | Done | |

| ID047 | Update black box diagram | ++ | J | 1 | 1 | Done | |

| ID048 | Writing Improvement stategy | ++ | F | 10 | 10 | Done | |

| ID049 | Doublecheck whole wiki | +++ | F | 3 | 3 | Done | |

| ID050 | Make interim presentation | +++ | F | 5 | 5 | Done | |

| ID051 | Battery research | +++ | C | 8 | 8 | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID052 | Finish chapter 6 | +++ | F | 10 | 8 | Done | |

| ID053 | Prepare Interim Presentation | +++ | T,S,C | 12 | 12 | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID054 | Search for Components | +++ | T, C | 16 | 14 | Done | |

| ID055 | Update Final Components List | +++ | S,T | 2 | 2 | Done | |

| ID056 | Review the Report | ++ | F | 10 | 10 | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID057 | Refine Report | +++ | F, S | 10 | 6 | Not done | To finish on the next week |

| ID058 | Upload Sprints to Microsoft Planner | +++ | S | 6 | 6 | Done | |

| ID059 | Solidworks motion simulations | +++ | T | 8 | 8 | Done | |

| ID060 | CoppeliaSim software introduction | +++ | C | 16 | 10 | Not done | |

| ID061 | 3D model video | +++ | S | - | - | Done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID062 | Refine Report | ++ | F, S | 4 | 4 | Done | |

| ID063 | Uploading minutes and weekly reports to logbook (past and upcoming weeks) | + | F | 3 | 3 | Done | |

| ID064 | Packaging solution | +++ | T,S | 10 | 11 | Not Done | |

| ID065 | CoppeliaSim Simulations | +++ | C | 10 | 16 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID066 | Packaging Solution | +++ | S | 6 | 6 | Done | |

| ID067 | Calculate MopBot weight | ++ | T | 6 | 6 | Done | |

| ID068 | CoppeliaSim Simulations | +++ | C | 10 | 10 | Not done | |

| ID069 | Wrighting the Overleaf paper | ++ | T, F | 9 | 7 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID070 | CoppeliaSim Simulations | +++ | C | 14 | 10 | Not done | |

| ID071 | Wrighting the Overleaf paper | ++ | T,F,S | 16 | 15 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID072 | Overleaf paper | +++ | T,S,F,C | 14 | 16 | Not done | |

| ID073 | CopeliaSim Simulations | +++ | C | 10 | 13 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID074 | Overleaf paper | +++ | T,S,F,C | 5 | 5 | Done | |

| ID075 | CopeliaSim Simulation | +++ | C | 12 | 13 | Not done | Just a few details missing |

| ID076 | Uploading the MS Planner and Logbook | ++ | T, S | 6 | 6 | Done | |

| ID077 | MopBot Manual | ++ | F,T | 8 | 7 | Not done | Almost finished |

| ID078 | Video | ++ | S | 12 | 8 | Not done |

| Task | Name | Priority | Responsible | Planned time [h] | Needed time [h] | Status | Notes |

|---|---|---|---|---|---|---|---|

| ID079 | Final deliverables | +++ | S,F,C | 5 | 8 | Done | |

| ID080 | Prepare final presentation | +++ | T | 8 | 8 | Done | |

| ID081 | Final report | +++ | C,F,T | 10 | 10 | Done |

3.11 Sprint Evaluations

In order to make their working week more productive, Team 2 planned in advance what each team member would do in the following week.At the end of each week, they analysed the work that had been done and if it had not been done, it was postponed to the following week and so on until the end of the project. To evaluate the sprints Team used Microsoft Planner and Microsoft OneNote.

3.12 Conclusion

The SCRUM methodology has undoubtedly been a valuable tool for the team to manage tasks as efficiently as possible. The team gives a very positive evaluation to SCRUM because it allowed each member to work in their area of knowledge, but it could also help another colleague if he needed help. However the team feels that the task divisions and analysis of the Sprints would have gone even better had the Covid-19 pandemic not occurred, as it allowed Team 2 members more time together which allowed for better task discussions.

4. Marketing Plan

4.1 Introduction

Activities and strategies in marketing have specific goals. One of the most important ones is making such products that satisfy customers while making profits for the companies that offer those products.

Bryan Eisenberg, the co-founder of BuyerLegends once said:

“Our jobs as marketers are to understand how the customer wants to buy and help them to do so.”[35]

Taking into consideration marketing marketers cannot concentrate on the product that their company is selling or service that it provides. Marketing is, in essence, more about selling the benefits rather than a product. This chapter is dedicated to figure out those benefits and to make a business strategy for Mopbot. Marketing strategy includes market, customer, and competitors analysis which Team will try to show using common tools like SWOT analysis, Porter’s five forces model, PESTEL analysis to provide research on different areas.

4.2 Market Analysis

Preparing market analysis will help the Team to get knowledge about the operational environment, the situation on the market and possibilities for development. Those significant factors will be later concluded in the SWOT analysis. Team will obtain information about potential customers, values that are important for them and competition on the market. Decision was made to prepare two-way analysis including internal and external analysis.

Business environment can divide the market into three levels:

- The micro-environment - including mission, vision, strategy, competences, resources processes;

- The meso-environment - including stakeholders, suppliers, competitors, marketing intermediaries, customers and public;

- The macro-environment - including economic, demographic, technological factors, natural and physical, political and legal, and social and cultural forces.

Looking at each level's factor will help the Team understand situation prevailed on the market. Figure 30 presents components of business environments.

Having the information from the market analysis the Team will be able to meet the customer's satisfaction, decrease the risk in the development process and prepare a valuable product in a more accurate way.

Service Robot Market

According to International Federation of Robotics (IFR) sales in service robots for professional use increased by 12 percent by the end of 2017 to a new record of 5.2 billion U.S. dollars. And the long-term forecast is positive too, with an expected average growth rate of 20 to 25 percent in the period 2018 - 2020.

Robotics in professional applications has already had a significant impact in areas such as agriculture, surgery, logistics or public relations and is growing in economic importance. There is a growing demand to monitor our everyday surroundings which results in increased and difficult-to-manage workloads and data flows. To meet this demand, robots will play an even greater role in the maintenance, security and rescue markets.[36]. Managers are forced by market and competition to replace human labor with machines. Robots are able to ensure quality and performance of processes.

The most impacting factors on robotics market growth are:

- rapid industrialization and automation - robots are able to make more precise operations and provide better customer services

- increase in labor cost - companies facing high labor costs are more likely to use service robots to reduce their expenses and remain quality;

- lack of skilled workforce - businesses dealing with lack of skilled employees are eager to buy precise robots with high capability;

- high initial investment - new technologies and increasing market competition, is expected to reduce investment costs of robots and accelerate the growth of the robotics market;

- creation of a safe working environment - robots do not experience injuries or fatalities in the workplace

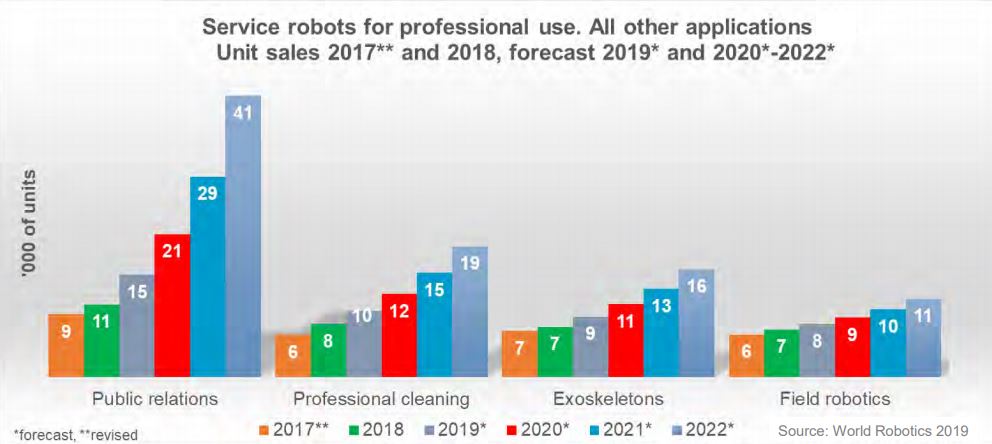

International Federation of Robotics providing annual reports about the robotisation on the world. In the Figure 31 below forecast in service robots for different applications is shown. According to the graph only up to the end of 2020 there will be 19000 robots used in commercial facilities professional cleaning.

Service robot market can be segmented in particular categories[38]:

- market by type - professional service robots, personal service robots

- market by application - professional applications (healthcare, defense, rescue and security, logistics, construction, field and others (like professional cleaning robots)); personal applications (domestic, entertainment and leisure, others)

- market by geography - North America, Europe Asia-Pacific, LAMEA

Figure 32 presents global service robot market overview.

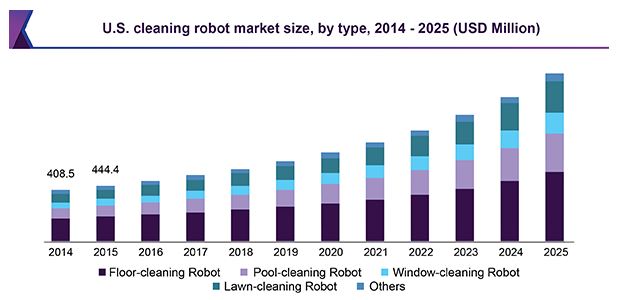

Cleaning Robot Market

Considering the cleaning robot market worth to remember is that it covers not only floor cleaning robots. To the cleaning robot category, there may be also assign robots for specific purposes such as a pool-cleaning robot, window-cleaning robot, and robotic vacuum cleaner. Cleaning robots can be divided into many categories[40]:

- Destination - personal and professional cleaning robot;

- Product - floor-, pool-, window-cleaning robot and others;

- User control - app-based, autonomous, digital assistant;

- Operating environment - indoor, outdoor;

- Application - residential, commercial, industrial, healthcare and others;

- Region - North America, Europe, Asia Pacific, rest of world.

Floor-cleaning robot is expected to hold the largest share, on the basis of product, of the cleaning robot market by 2025; the growth of the market for this technology can be attributed to the popularity of floor-cleaning robots in the residential sector, which has helped the market to grow at a rapid pace. These robots are equipped with functions such as navigation control systems and sensors (distance counter, gyro, ultrasonic, laser, and bumper switches), which are specifically used to detect obstacles and prevent collisions. Figure 33 visualizes an increase in interest for cleaning robots in the US market between 2014 and forecasting up to 2025.

The largest share of cleaning robot market by category of product is assumed to be floor-cleaning robots. Rapid growth in their popularity caused a large increase in the market for this technology. Manufacturers are bringing as many new functions to their products as they can deliver, for example, different navigation control systems or brushes drive control. Those things are especially used in case of collision prevention, litters localization, collision and fall prevention.

Professional Cleaning Robot Market

Industrial cleaning robots can bring a broad spectrum of business benefits, depending on a company’s needs. Mainly what matters is the cost reduction, however, facility managers are looking for more developed solutions right now. Their aim is to be more efficient and effective using new processes, introducing sustainable practices or providing changes in streamline operations. Because of the lack of effectiveness and poor service cleaning companies are losing up to 55% of their customer base every year. [42] This can be one of the factors why companies decided to choose to buy a cleaning robot. In current situations, there are few companies that are producing automated industrial cleaning robots. Industrial cleaning robots that are almost fully autonomous are shown in Table 33. The table contains also information about the average value on each category of comparison. It will enable us the determine or have a first look on which features should be present in our robot.

| Name of robot | Link | Picture | Operation time[min] | Cleaning width [mm] | Cleaning performance [m²/h] | Container volume [l] | Height [mm] | Weight [kg] | Maximum estimated cleaned area [m²] |

|---|---|---|---|---|---|---|---|---|---|

| KEMARO-800 | Kemaro-800 |  | 120 | 800 | 1000 | 40 | 300 | 30 | 2000 |

| NEO Avidbots | NEO Avidbots |  | 300 | 660 | 2851,2 | 120 | 1150 | 476 | 14256 |

| fybots sweeperXL | fybots sweeperXL |  | 360 | 1200 | 1200 | 30 | 920 | 240 | 7200 |

| Intellibot® Swingobot 2000 | Swingbot 2000 |  | 240 | 700 | 1050 | 90 | 1285 | 252 | 4200 |

| Tennant T7AMR FEATURES | Tennant |  | 240 | 650 | 2660 | 110 | 1450 | 492 | 10640 |

| Average value: | 252 | 802 | 1752,24 | 78 | 1021 | 298 | 7659,2 |

Regions that invest the most in cleaning robots are North America, Asia and Western Europe. North America is the largest market for industrial automation, and the market is growing rapidly. This will fuel the demand for industrial cleaning robot in the region. The region is likely to account for market shares of 42.73% and 48.32% in terms of unit shipment and revenue, respectively, in 2022. North America is followed by Europe, led by Germany and Italy where industrial robot penetration is more and sales of industrial robots are high.[43].

Regions like Middle Eastern Europe and Latin America have not been popularised with cleaning robots. It brings our team a great opportunity to fulfill this gap in market demand for industrial cleaning robots.

4.2.1 Problem Statement

Looking into the budget of any company it is possible to see there a constant part of expenses that are dedicated to the area connected with the operating of a company. Those are resources allocated for the paper to copy machines, pens to the office, food for conferences and also for cleaning services. As those companies intend to have as little money allowed for cleaning services (in order to put it into other expenses) there is a need to have service on a higher possible level at the lowest price. There are very few things that are able to be change in case of service pricing and it is a hard choice for managers to make decisions within this topic.

4.2.2 Internal Analysis

7S Model of McKinsey for internal analysis

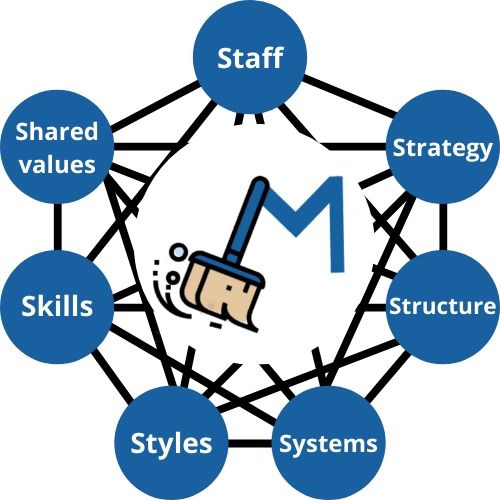

In order to prepare an analysis on our Team - micro-environment that Team works in, it was decided to choose the 7S McKinsey model as a framework. The assumption of that framework is that if every factor is in good condition, the group is working in harmony without any adversities and barriers. The specific layout of the McKinsey model is shown in Figure 34. It is demonstrated there, that each variable is connected with another. Imbalance in any of them ruins the proper work of the group. Analysis of the McKinsey model will be helpful in the case of the preparation team SWOT analysis.

Strategy - Purpose of the business and the way the organization is doing to get a competitive advantage.

The team contains four different experiences and skills to people. The key to success will be the usage of everybody's skills and knowledge in particular areas to obtain the best results. Being an expert in a specific field of study will be crucial in fulfilling the goals properly.

Structure - Activities division and coordination of the team.

Due to the different skills and experiences mentioned above, some tasks are divided. Difficult decisions are made in a democratic way - the majority of the team is respected. Nevertheless, each member of the team is able to give an opinion about any topic.

Systems – Measurement procedures, reward, and resource allocation.

The team is able to monitor progress by every Thursday's meeting with supervisors. It is a great opportunity to know the teacher's opinion about particular actions and also to hear feedback about things that were done in a good or bad way. Each of the team members has access to the Wiki page, common Google Drive with project files. It enables each participant to have a view on what each member is working.

Shared Values - Corporate culture and work ethic.

The shared value that each team member follows is the motivation to create a remarkable and best possible product. Despite cultural, linguistic and specialization differences, everyone aims at doing excellent work.

Skills - The organization's core competencies and distinctive capabilities.

The team consists of four students from different countries and from different study areas, however, each one had at least little contact with engineering and product development. Tomas: Mechanical Engineering, Corina: Telecommunications, Frederique: Civil Engineering and Szymon: Business and Technology. Each one does not have any problem with popular tools used during project development.

Staff - Team members and their general capabilities.

A major amount of decisions is made together by all members of the group. Although everyone has different priorities, all of us are working to successfully complete a common goal.

Style - Typical behavior patterns of key groups, such as managers, and other professionals.

The team is working using the scrum method - with the usage of sprints and its methodology. In such a way of working there is no need to have a hierarchy. What is important, is that communication and the open-mindedness of each team member will never be degraded.

4.2.3 External Analysis

External analysis cover meso- and macro-environment. Variables that Team want to analyze are presented in Porter's Five Forces model - Figure 35 and PESTLE model. Those frameworks will give us input data and information that will be mainly used in threats and opportunities in a product SWOT analysis.

4.2.3.1 Porter's Five Forces model

Starting a business is a complex process. It is almost impossible to run a successful business without previously made analysis. In our research, we should include each factor that has an impact on the activity of our company. There are many tools that can use to work on that analysis. It can be used as a framework to analyze market competitiveness. It enables us to understand the strengths and weaknesses of the industry as well as its profitability and development perspective. Porter's model contains research on the number and power of a company’s competitive rivals, potential new market entrants, suppliers, customers, and substitute products. Investigation within those areas can be useful in case of creating a more competitive business strategy.

Competition in the industry

Force of competition marks its presence in the number of competitors' businesses and their ability to contend with a particular company. In the case of a greater amount of competitors and their goods or services, our company has less power to raise on the market. This “fight” between the companies can be described as a price valuation, new-tech usage or simply providing the innovation. As a company providing cleaning robots for cleaning industrial areas, we enter the market with already stated brands and products. Companies like Avidbots and fybots can be mentioned as examples. Our aim should be then creating a unique service that we can provide or time-consuming building relationships with business customers. Fortunately, previously mentioned companies do not operate on regions of central and eastern European countries - that creates an opportunity for us to raise our business on an unfulfilled market.

Potential of New Entrants into an industry

Operating on a growing market is always a threat to the company. It is easier for new companies to enter into that market because customers do not know the product, features, and option that each competitor offer. The team must think about what makes cleaning robots business attractive and try to suit to those factors. Due to the existence of cleaning robot companies, our robot will not be something new. Companies like Karcher have already understood that simple cleaning equipment is not enough nowadays. Introducing products before them would be a great opportunity to decrease potential new entrants into an industry for Karcher and other companies.

Power of Suppliers

The power of suppliers mainly determines the availability and price of raw materials. It is regulated by a number of suppliers, their supply possibilities and costs and also costs of change from one supplier to another. Components that will be mainly needed are electric parts. In this area, our team has a lot of choices. More problematic for us will be mechanical parts. In the case of chassis and storage containers and v-shaped pushing block usage of 3D printing is needed. We are able to make it with another plastic material, however, negotiations with the external suppliers should be needed. In case of such specific shape components price could be jacked up to unimaginable value.

Power of Customers

Customers factor refers to their ability to play on the price level and as everyone can imagine it is about reducing the price. Regulation of the price is influenced by a number of customers, the level of importance of each customer and the ability to obtain new customers on the market. Each of these factors has an impact on pricing negotiations. Our product is targeted at business customers, mainly shopping centers and other industrial facilities. That is why service costs for each customer can be negotiated individually. It is an advantage for our business because it will help us build a base of loyal customers and relationships. In today's world, business is more about building good relationships in view of valuable partnerships on which both sides win.

Threat of Substitutes

The threat of substitutes refers to substitute services or goods that can be used in place of our product. Creating a unique product that can not be changed to any other one is more powerful in case of pricing. Our team has tried to develop such a product that will possess unique features. There is a risk of substituting our robot with simple human service which could be more beneficial for small areas. To fulfill this gap in our activity, a long-term solution is to create smaller cleaning bots target to deal with a litters in smaller, less accessible areas.

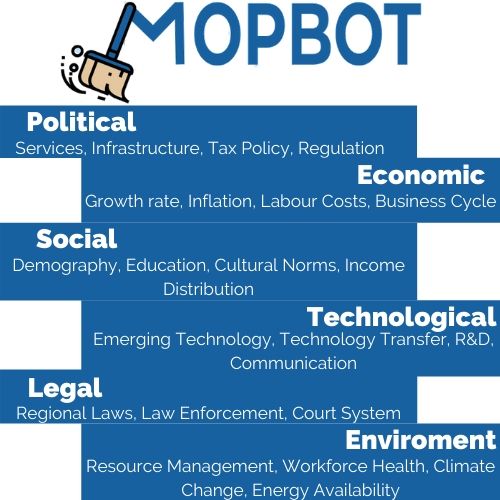

4.2.3.2 PESTLE Analysis

PESTLE analysis is a tool used to identify the macro (external) forces facing an organization [44]. Each letter represents Political, Economic, Social, Technological, Legal and Environmental aspects. Diving into those aspects will show the team what impact our product may or may not have.

- Political

Our product does not have a political impact on the society. This category is not such relevant in case of our project.

- Economic

Introducing the usage of our product to shopping centers or industrial facilities will bring money to the market. Consumption of goods is power for economic growth.

- Social

Creating social awareness about the waste management strategy for the planet would be main goal within this factor.

- Technological

Using technology for minimizing risks of health injury and maximizing efficiency is becoming more and more common in business management. Providing new solution that can solve some issues or will support effectiveness of the business will be worth to invest.

- Legal

Regarding legal aspects, our product will follow all of the regulations, not having a particular impact on this area.

- Environmental

Collecting litters is a very important part of waste management policy. Creating a product that supports this approach will help to reduce the carbon footprint for each of the created wastes.

4.3 SWOT Analysis

SWOT analysis is a powerful and simple tool to develop business strategy. It can be used by start-up, existing company or other subjects. Acronym SWOT stands for Strengths, Weaknesses, Opportunities, and Threats. The first two factors can be described as internal ones - things that we have control and direct impact on. Opportunities and Threats can be marked as external factors - depending on the larger environment. Those are the things that are usually not changeable by us, such as component price or competitors.

SWOT analysis are presented in the Figure 37 for Team analysis and Figure 38 for product analysis.

4.3.1 Team SWOT Analysis

4.3.2 Product SWOT Analysis

We have to remember that SWOT analysis proclaims not about all considered and described factors, but identify key factors that can have a main impact on the future of the company or the success of a specific project. We need to try fight our weaknesses and threats as much as we can. It will be one more step forward successful project.

4.4 Strategic Objectives

Strategic objectives are the steps and deliverables, which are established by a team of stakeholders in order to realize the goal. Objectives help across the team to understand the goals and to determine whether the strategy is effective and the tactics are being well executed. The most important thing in an objective setting is to provide specified outcomes able to be done in a specific time range. Our team decided to set them with the usage of the SMART approach which specifies factors that draw closely setting of the goal. Each letter specify values that our objectives should posses.

| Letter | Factor |

|---|---|

| S | specific, significant, stretching |

| M | measurable, meaningful, motivational |

| A | agreed upon, attainable, achievable, acceptable, action-oriented |

| R | realistic, relevant, reasonable, rewarding, results-oriented |

| T | time-based, time-bound, timely, tangible, trackable |

General mission and vision strategic objectives:

Economical strategic objectives:

- Develop a business based around litter collection robots which are both profitable and economically sustainable.

- Maintain growth based on the cooperation with cleaning companies. As a next phase to open for the private customers.

Customer/Learning strategic objectives

- Introduce an innovative solution into an existing market.

- Build relationship with customers (companies) by introducing a high-quality product and service.

- Provide advertising campaign to spread “clean planet/city” awareness. To encourage society to live in a more sustainable way - probably as a long term action.

Environmental Strategic objectives

- To prepare an autonomous solution to shopping centers wastes collection system.

- To adapt processes to be efficient as possible to reduce carbon footprint.

- To continually adapt to best environmental practices.

- To spread awareness to encourage more environmentally friendly practices.

Measurable and time-framed objectives in terms of waste robot project:

- Create a complete model before 30 April 2020

- Upload packaging solution to the wiki 13 May 2020

- Conduct simulations and functional tests before 02 June 2020

- Complete the entire WIKI website before 12 June 2020

- Create an official website where people can buy our product by the end of September 2020

- Create a database of people interested in purchasing our product at the beginning in Portugal- by the end of November 2020

- Popularize and promote our product in other countries thanks to strong advertising (such as Slovenia, Poland, Hungary - in central-western European countries) - between February and May 2021 - depending also on the interest in our product.

4.5 Strategy/Targeting/Positioning/Brand

Basing on the market analysis Team decided focus on the Business to Business (B2B) market. As a target group team have chosen the managers of shopping centers. These customers will be the most interested in our product. Below the positioning maps for our product in Figure 39 and Figure 40

Considering positioning strategy, it can be assigned not only to products, but also to services and brands. Knowing the benefits that MopBot brings team will analyse it as a product. Positioning strategy includes the way the product is defined by consumers on important attributes, comparison with competing products and simplifying the buying process for the customers. In order to prepare superb positioning Team had to make particular tasks like:

- define intended positioning for our product - our product will be distinguished by price, performance and quality

- design and implement a marketing mix strategy within intended positioning would be accomplish - this point will be more described in Section 4.6

- identify possible competitive assets - in case of industrial cleaning robot the competitive assets will be price, cleaning performance, operation time and mobility of the product

- monitor and adapt positioning strategy over time to meet customer needs - how the Team would like to do it is described in Section 4.8

Team decided to create remarkable product which can be noticed on the market. To build brand awareness, creation of characteristic sign that would be connected to our brand was necessary. Thinking about the name and the logo, team has many ideas, that can be well developed, although final decision was to chose the name MOPBOT. Team considered that name MOPBOT could have been already used. During supervisors' meeting it turned out that one of the existing products has that name connected to mop. MOPBOT-D was designed by Indian company Pata Electric [45]. Making research about that Team found out that name MOPBOT is not registered on World Intellectual Property Organization (WIPO) database. That ensured us that we can use MOPBOT as a name for our product. Next step was to create a logo for our brand.

As it can be seen in Figure 41 Team's decision was to concentrate around mop, as a recognisable sign. To do that additional commercials were created and can be seen in Figure 42. As a slogan the Team chose “Cleans more than You think”.

Decision was to chose white and blue as dominating colours. Those colors in team's opinion are the most connected to cleaning area.

4.6 Adapted Marketing-Mix

The classic “4P's” marketing - product, price, place and promotion have been the fundamental of marketing tactics for many years. Over time, as the service sector increased, 4P's expanded to 7P's, including people, processes and physical evidence.

It is worth noting, however, that both the 4P's and 7P's concepts include marketing instruments from the point of view of the company, not from the client. That is why, in 1990, Robert Lauterborn developed the 4C marketing formula, shown in Figure 43. It covers the same elements as the classic 4P, but seen through the eyes of the consumer.

4C marketing consists of four elements. The first is customer. His needs, motivations and goals are in the marketer's focus. His task will therefore be to discover these desires, which implies a much greater emphasis on marketing research. The “product” known from the 4P model is therefore secondary to the prior recognition of the market.